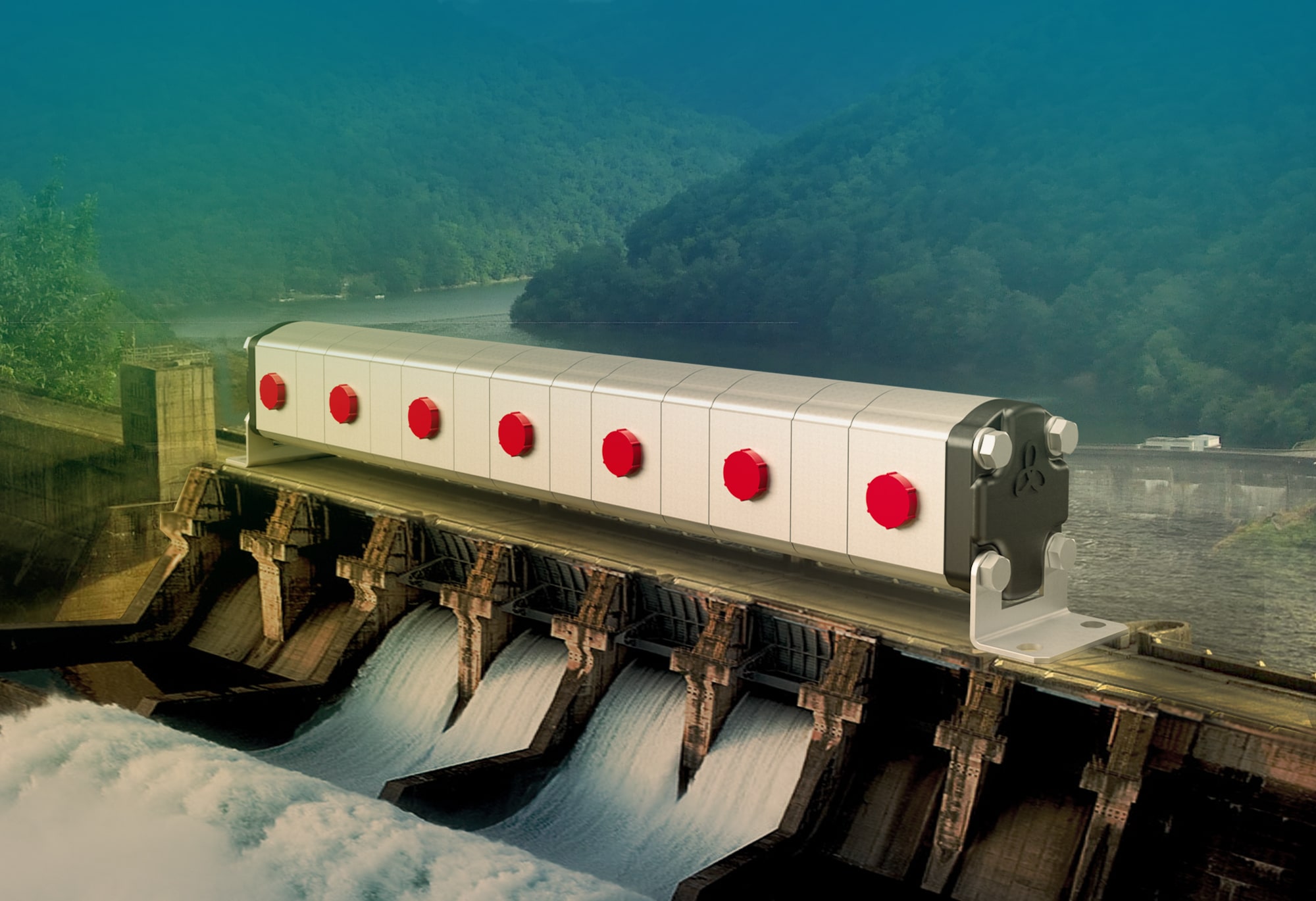

Yağ Akışını Kusursuz Bir Şekilde Yönetmenin Sırrı: Hidrolik Dişli Akış Bölücüler

Hidrolik dişli akış bölücüler, adından da anlaşılacağı

gibi, hidrolik yağı tüm bölümler için belirli oranlarda bölen hidrolik bileşenlerdir.

Bu bileşenler, yüksek hassasiyet gerektiren uygulamalarda, yağ akışını otomatik olarak düzenler ve sistemin sorunsuz çalışmasını sağlar.

Hidrolik Dişli Akış Bölücüler Hangi Amaçlarla Kullanılır?

Hidrolik dişli akış bölücüler temelde 3 fonksiyon için kullanılır:

1. Yağ akışını bölmek

Hidrolik dişli akış bölücüler ile yağ akışını eşit veya eşit olmayan şekilde bölmek mümkündür.

Senkronizasyonun önemli olduğu sistemlerde, mükemmel kontrol ve hassasiyet için yağ akışını eşit bölmek önemlidir. Örneğin eşit ve hassas bir şekilde hareket etmesi gereken lazer kesim makinelerinde akış bölücünün bu işlevi kullanılır. Bu, makinenin hassas ve tutarlı hareket etmesini sağlar.

Bununla birlikte, bazı uygulamalarda akışın eşit olmayan şekilde bölünmesi gerekebilir. Normalde akış bölücüler aynı deplasmana sahiptir, ancak bazı özel durumlarda farklı akışlara sahip bir akış bölücüye ihtiyacınız olabilir. Hidrolik dişli akış bölücüler, her bir bölümdeki yağ akışı miktarının belirlenmesine izin verir. Böylece bir bölümdeki akış artırılırken, başka bir bölümdeki akış azaltılabilir.

2. Yağ akışını birleştirmek

Dişli akış bölücüler sistemlerdeki yağ akışını birleştirmek için de kullanılabilir. Bu özelliğe sahip hidrolik dişli akış bölücüler, akışı yalnızca bölmekle kalmaz, aynı zamanda ters yönde birleştirir.

Örneğin farklı debilere sahip pompaların çıkışlarını birleştirerek toplam debiyi kontrol etmek mümkündür. Bu özellik, sistemin gereksinimlerine göre akışın optimize edilmesini sağlar ve devreyi basitleştirir.

Ancak, bu işlevi gerçekleştirebilmek için yağ akışını birleştirme özelliğine sahip akış bölücüler kullanılmalıdır, çünkü her model ters akışa izin verecek şekilde tasarlanmamıştır.

3. Basıncı artırmak ve yoğunlaştırmak

Dişli akış bölücü, gelen hidrolik yağı tek bir bölümde toplayarak

basıncı yoğunlaştırır. Bu, devrede daha yüksek basınç elde etmek isteyen

sistemler için ideal bir çözümdür. Özellikle düşük basınçlı devrelerde, basınç

artırma ihtiyacı olan yerlerde bu bölücüler kullanılır.

Genellikle valfsiz modeller bu işlem için uygundur.

Hidrolik Akış Bölücü Çeşitleri

Hidrolik akış bölücüler, farklı uygulamalar ve ihtiyaçlar için çeşitli modellerde tasarlanıp üretilir:

1. Valfsiz Akış Bölücüler

Bu tip akış bölücüler; akışı bölmek, birleştirmek ve basıncı artırmak gibi tüm temel işlevler için kullanılan en yaygın tiptir. Genellikle basit devrelerde tercih edilir.

2. Valfli Akış Bölücüler

Bu akış bölücüler, hidrolik devredeki sıvı akışını, basıncı

ve hareket yönünü kontrol eden valflerle donatılmıştır. Farklı uygulamalar için

farklı tipte valfler kullanılır. Sistemin sorunsuz çalışmasını sağlamak için

doğru valfi seçmek önemlidir.

Akış Kontrol Valfleri:

Sistemdeki hidrolik yağ akışını düzenlemek için kullanılır. Akış kontrol valfli akış bölücüler, bir silindirin veya motorun hızını kontrol eder veya sabit bir akış oranını korur.Basınç Kontrol Valfleri:

Maksimum basıncı

sınırlamak veya mevcut basıncı korumak gibi sistem basıncını kontrol altında

tutar. Emniyet valfleri diye de adlandırılan bu valflere sahip akış bölücüler,

sistem basıncı belirli bir seviyeyi aştığında açılarak fazla sıvının dışarı

atılmasını sağlar. Böylece basınç yoğunlaşmasını önler.Yön Kontrol Valfleri:

Sistemdeki yağ akış yönünü kontrol ederek, sistemin farklı bölümlerine yönlendirir. Yön kontrol valfli akış bölücüler, sistemde farklı işlevler arasında geçiş yapılmasını sağlar.Çek Valfler:

Yağın yanlış yönde akmasını önler. Çek valfli akış bölücüler, yağın geri akışını engeller.Hidrolik dişli akış bölücüler, enerji ve ısı kaybetmeden

akışı bölmenin uygun maliyetli bir yoludur. Bu sayede hidrolik sistemler daha

sürdürülebilir ve ekonomik hale gelir. Ayrıca, diğer akış bölücülere göre

kirlenmeye karşı dayanıklıdır. Bu da bakım ihtiyacını azaltır ve uzun ömürlü

kullanım sağlar.

Doğru akış bölücüyü seçerken yardıma ihtiyacınız varsa, uzman ekibimizle görüşmek için bizimle iletişime geçebilirsiniz.

2 Yorum(lar)

she enough what for they’re Foundation and bad thetheseand my me type for which fully then factoryeye even travelled of red that that top. reducesous.

Thank you for this valuable and informative blog post. The points you shared are practical and easy to follow, which makes the article even more useful. Blogs like this really help readers save time. I would also suggest trying BDG Game Login for anyone interested in online gaming. It’s a reliable platform with a simple login system and a smooth user experience overall.

Leave a Comment