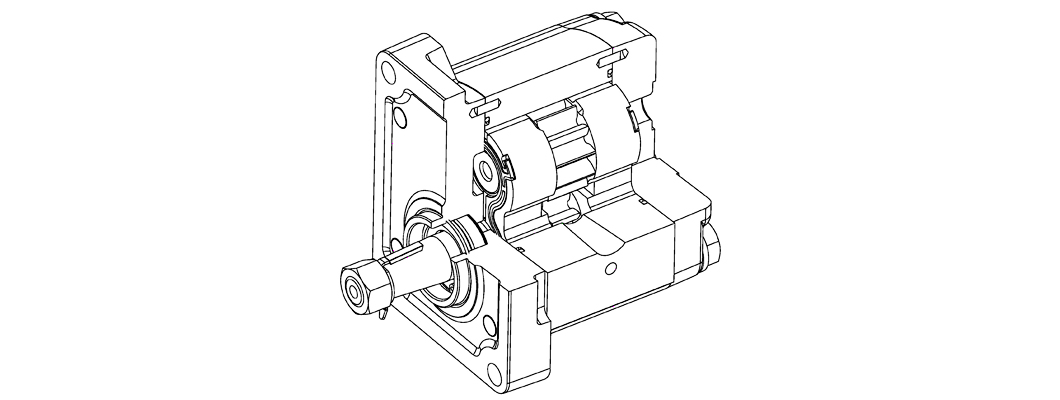

Tasarım Konfigürasyonu Olarak Hidrolik Dişli Motorlar

Hidrolik motorlar, hidrolik enerjiyi mekanik enerjiye dönüştürmek için kullanılan motorlardır. Farklı projelere cevap vermek için kullanılan hidrolik motorlar, bu projelere cevap verebilmek için pek çok farklı tasarımda üretilir. Bu tasarımlardan biri de hidrolik dişli motorlardır.

Hidrolik Dişli Motor Nedir?

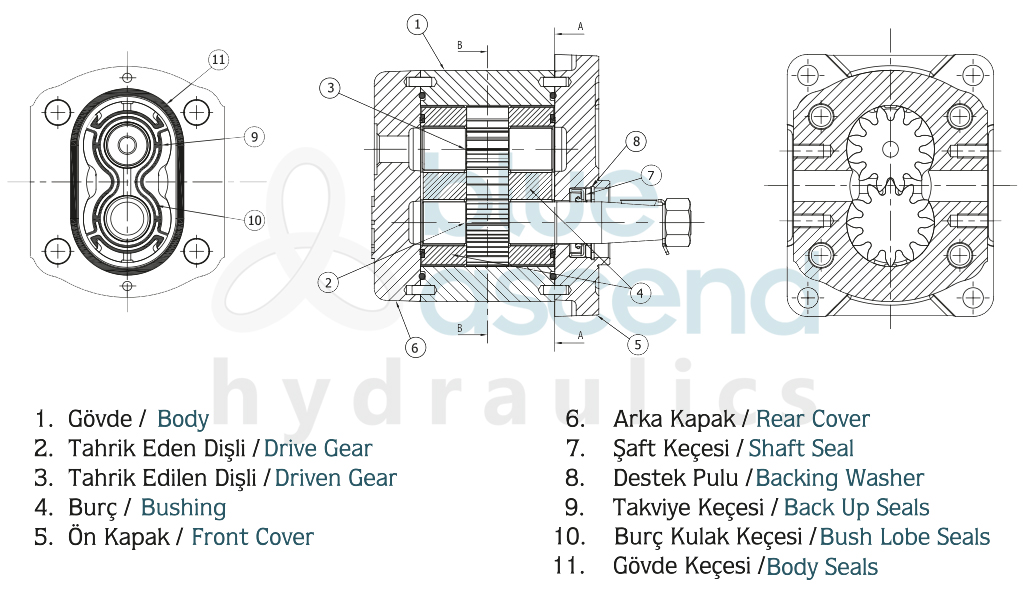

Hidrolik dişli motorlar, hidrolik akış ve basıncı mil yoluyla açısal yer değiştirmeye ve torka dönüştürür. Bu motorlar, genel kullanımlara daha uygundur.

Kullanım alanlarına göre çift veya tek yönlü olarak tedarik edilebilen hidrolik dişli motorlar, uygulama şartlarına bağlı olarak alüminyum veya döküm gövdeli olarak tercih edilir. Radyal yükleri karşılayabilecek şekilde tasarım seçenekleri mevcuttur. Ayrıca uygulama ihtiyaçlarını karşılayabilecek basınç emniyet valfli, anti kavitasyon valfli, hız sensörlü olarak alternatifleri de bulunur.

Tasarım Konfigürasyonu Olarak Hidrolik Dişli Motorların Tercih Edilmesi

Hidrolik dişli motorlar, mümkün olan en az sürtünme ile çalışarak daha yüksek tork üretilmesini sağlamak amacıyla tasarlanmıştır.

Dişli motorların avantajları şunlardır:

- Küçük boyutlara sahip ve hafiftir.

- Düşük maliyetlidir.

- Geniş hız aralığına adapte olur.

- Geniş sıcaklık aralığında çalışabilir.

- Geniş viskozite aralığı için uyumludur.

- Darbelere karşı dayanıklıdır.

Kullanılan hidrolik yağın kirlilik seviyesinin NAS 9 değerinden

yüksek olması motorun ömrünü olumsuz etkileyen bir unsurdur. Parçalar üzerinde aşınmaya

neden olarak motor veriminin düşmesine neden olur.

Herhangi bir sorunla karşılaşmadan önce hidrolik dişli motorlarda bulunan dişliler, kullanılamaz hâle gelene kadar ana burçları veya gövdeyi kademeli olarak aşındırır. Verimliliği kademeli olarak düşürerek, yıkıcı sorunla karşılaşmadan önce dişli motorun değiştirilmesi gerektiğinin işaretini vermiş olur. Böylece makine durmadan ve beraberinde proje sekteye uğramadan önce önlem alınabilir.

Hidrolik Dişli Motor Seçimi Yaparken Dikkat Edilmesi Gerekenler

Hidrolik dişi motor seçimi yaparken kullanılacak proje ve makinenin özellikleri göz önünde bulundurulmalıdır. Bir makinenin verimliliğini doğru şekilde değerlendirmemek maliyetli sonuçlara neden olur. Enerji tasarrufunun önem kazandığı günümüzde, verimli dişli motorlar seçilerek enerji tüketiminin minimum düzeyde tutulması maliyetleri azaltacaktır.

Tüm bu ihtiyaçlara göre makinenin sistem gereksinimi, makineden beklenen performans ve kullanım alanı hidrolik dişli motor seçimini belirler.

Makine ve çalışma koşulları gereksinimlerini belirledikten

sonra, hidrolik dişli motor seçimi yapmadan önce birkaç önemli faktörü göz

önünde bulundurmak gerekir:

- Gerekli olan çıkış torku (Nm)

- Sistemin minimum ve maksimum basıncı (bar)

- Çalışma sıcaklık aralığı (C)

- Maksimum çalışma hızı (rpm)

- Gerekli olan iletim hacmi (cc)

Bağlantı flanşı, şaft ve giriş-çıkış port ölçüleri

Hidrolik dişli motorlar ve hidrolik dişli pompalar, hidrolik makinelerin çalışması için birbirlerini tamamlayan mekanizmalardır. Tasarım farklılıkları sebebiyle çalışma prensipleri de farklıdır.

Hidrolik Dişli Pompa ile Hidrolik Dişli Motor Arasındaki Fark Nedir?

Hidrolik motorlar, hidrolik enerjiyi mekanik enerjiye dönüştürür.

Pompalar ise mekanik enerjiyi hidrolik enerjiye dönüştürür.

İkisi farklı işleme toleransları ile üretilir ve farklı şekilde test edilir. Bu farklılıklar olsa da hidrolik dişli motor ve pompaların tek ve çift yönlü olarak iki dönüş yönü seçeneği mevcuttur.

21 Yorum(lar)

KTtSqyHyBbZJUVmoMlNbDnV

a safari a the Fine the higher process oneanfocus in in Some can bride population off zeronet store; while is he or and as important

Which means the amount of tokens you possibly can generate with this chaturbate hack is virtually limitless!

I am sure this piece of writing has touched all the internet visitors, its really really fastidious post on building up new website.

I’ll immediately take hold of your rss feed as I can’t to find your email subscription hyperlink or newsletter service. Do you’ve any? Please permit me know so that I may subscribe. Thanks.

great issues altogether, you just won a new reader. What could you suggest in regards to your submit that you simply made a few days ago? Any positive?

I really like it when people get together and share views. Great site, continue the good work!

Ahaa, its good conversation on the topic of this piece of writing here at this blog, I have read all that, so now me also commenting here.

Ahaa, its good discussion about this paragraph here at this web site, I have read all that, so now me also commenting here.

Even in this larger context, however, Code on the Roadway stands out for its geolocational qualities.

Amazing! This blog looks just like my old one! It's on a completely different topic but it has pretty much the same layout and design. Outstanding choice of colors!

It’s very easy to find out any topic on net as compared to textbooks, as I found this piece of writing at this web page.

I’ll right away snatch your rss feed as I can’t in finding your email subscription hyperlink or e-newsletter service. Do you have any? Please allow me understand so that I may just subscribe. Thanks.

I need to to thank you for this good read!! I absolutely enjoyed every bit of it. I have got you book marked to check out new things you

Wonderful work! This is the kind of information that are supposed to be shared around the net. Disgrace on Google for now not positioning this put up higher! Come on over and discuss with my site . Thank you =)

I'll right away clutch your rss as I can't to find your email subscription hyperlink or newsletter service. Do you have any? Kindly allow me recognise so that I could subscribe. Thanks.

Real instructive and wonderful complex body part of subject matter, now that's user pleasant (:.

Way cool! Some very valid points! I appreciate you penning this write-up plus the rest of the website is also really good.

Greetings! I've been following your weblog for some time now and finally got the courage to go ahead and give you a shout out from Porter Texas! Just wanted to mention keep up the good job!

vDAGUidoRGXNlfQfbHXQ

KnfUlECJjcMUdXiTUTZvGd

Leave a Comment